Motor Controllers

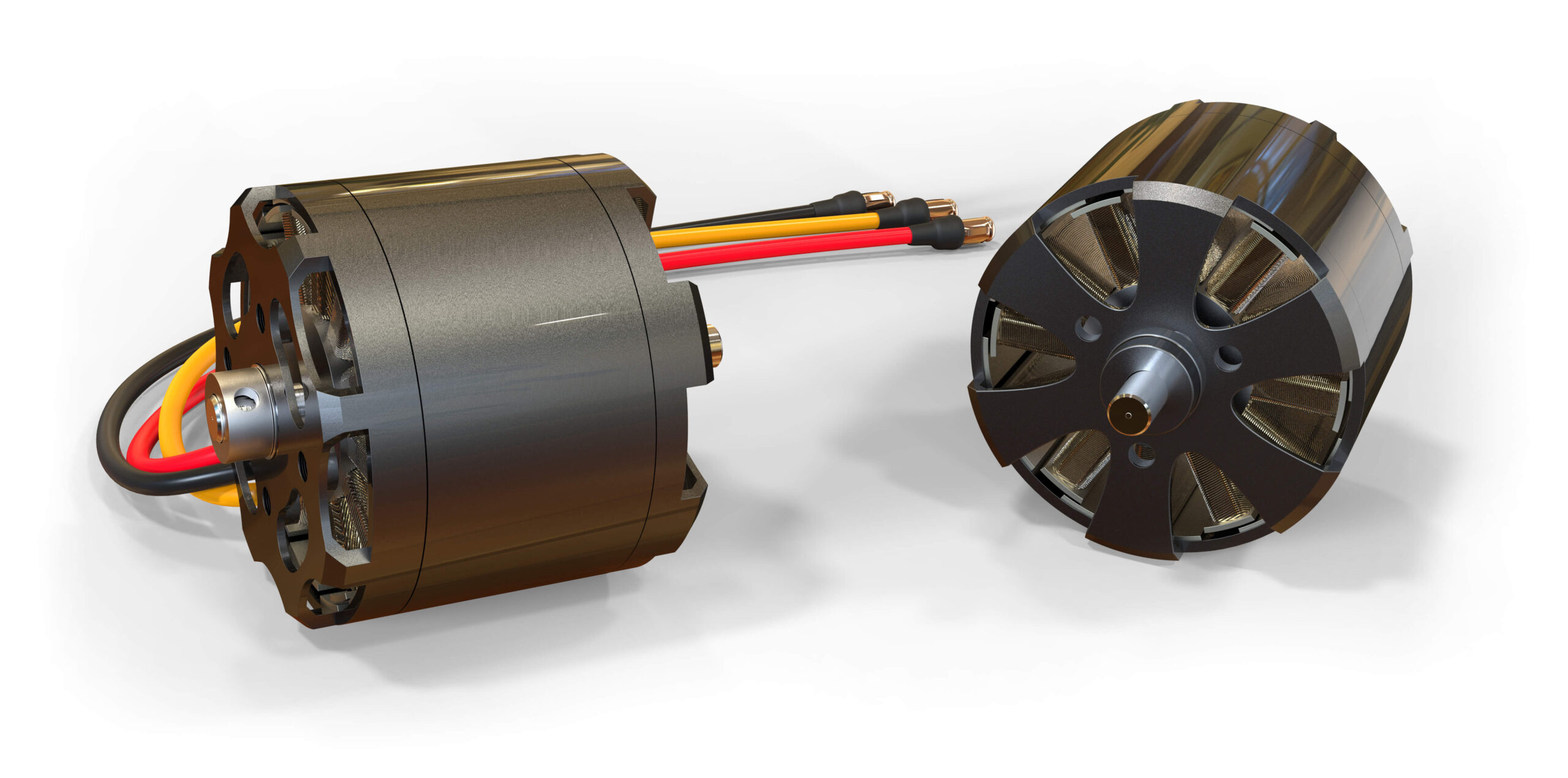

Embdes motor control solution is packed with state-of-the-art electrical machines, embedded systems, power electronics, and control systems to cater the need of modern electrical vehicles across different motor types such as BLDC, PMSM, SRM and induction motors. It measures and precisely regulates system characteristics including motor speed, torque, voltage and current. Controller has self-protection capabilities to detect a malfunction if found by safeguarding the safety of the vehicle.

By keeping the present trend and futuristic EV opportunities in our vision, we have our own advanced algorithms like FOC, Field-weakening, regenerative braking and lockstep dual core solution. Embdes sustainable and rugged motor controller hardware which can be customized according to the customer requirements and motor spec.

We have an ecosystem of experienced Automotive Domain Experts, Engineers for hardware, software, mechatronics, application development and Industry Partners.

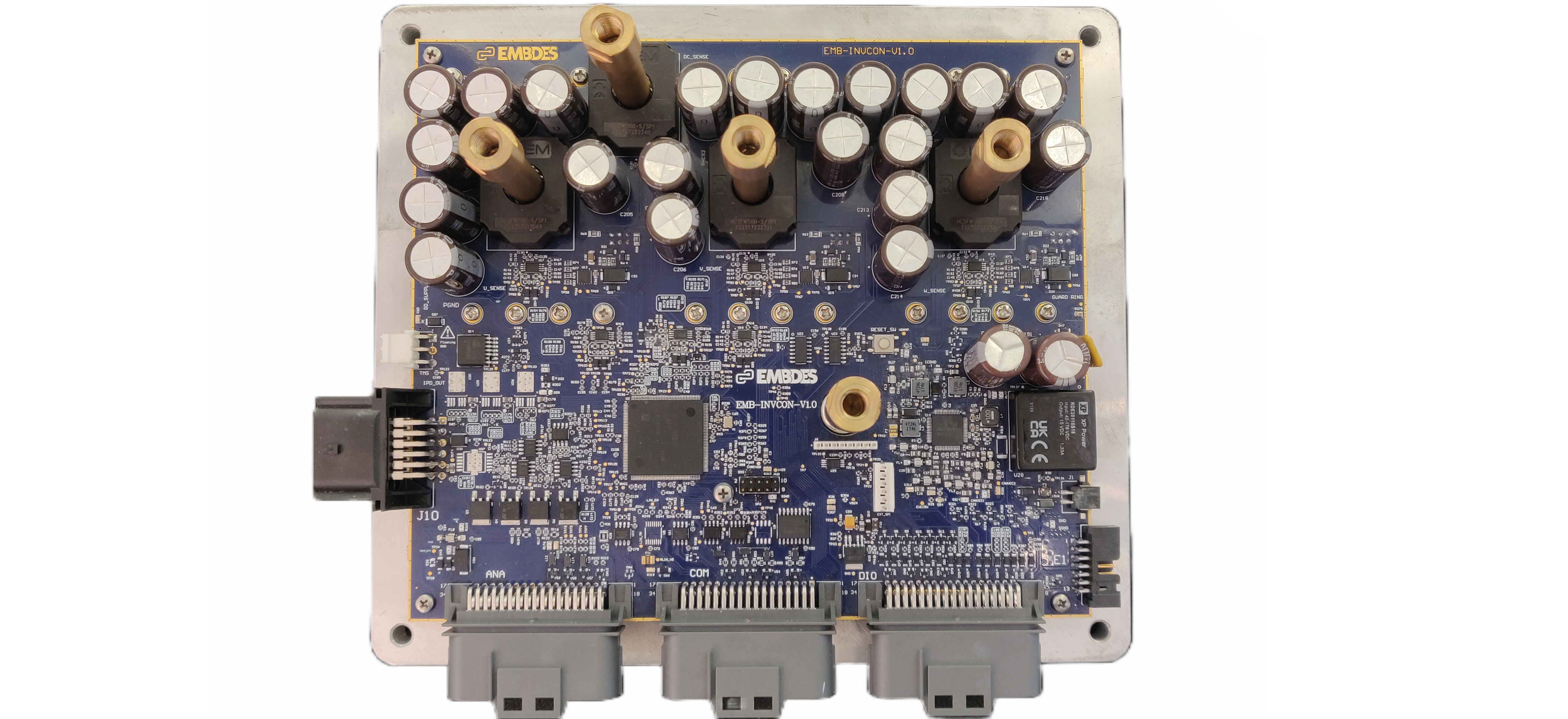

Low Voltage Inverter for 2/3-Wheeler Traction Motor Control

The low voltage inverter for 2/3 wheelers traction motor control is a reference design using the brochure RH850/C1M-A1 MCU and analog products for high power 48V motor control applications.

Includes inverter hardware design files (schematics and Gerber) and peripheral sample code (for motor control unit and resolver-to-digital converter), allowing for fast evaluation and development based on real-life use cases.

System Benefits

- The power stage can drive up to a 10kW motor. Proper heat sinks and temperature monitors are provided for a complete system-level validation for the OEM/Tier 1.

- Support to scale the 48V power stage of the inverter as per customer requirements.

- Support connection with vehicle I/O, brake sensor, accelerator, gear, and drive modes along with PWM output for the digital cluster.

Technical Specification

Rated Power |

|

Peak Power |

|

Nominal Voltage |

|

Battery Voltage Range |

|

Continuous and Peak Current |

|

Current Measurement |

|

Motor Controller Temperature Range |

|

Configuration |

|

Communication |

|

Protection |

|

Types of Feedback from Motor |

|

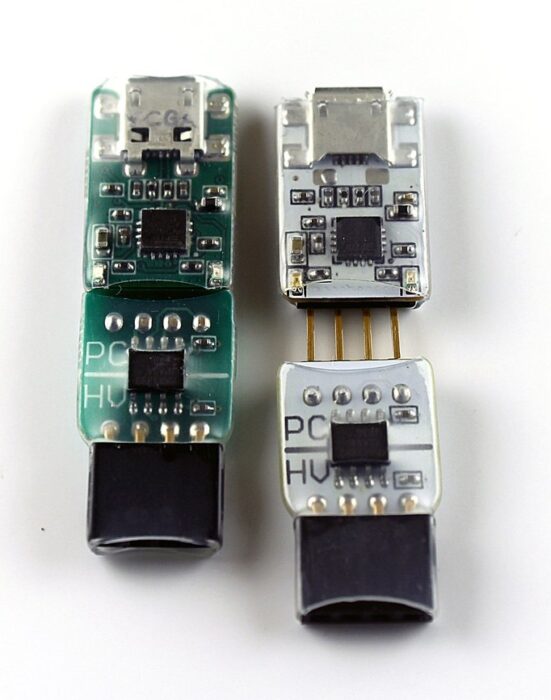

Programming & Control Interfaces |

|

Power Board |

|

HW Safety and Security |

|

Hardware Fault Generation |

|

Other Features |

|

Embdes has designed and developed a reference platform for motor control inverter application for 2Wheeler/3Wheeler. This reference platform is sellable via distribution channel.

Embdes can take custom motor control design based on the application requirements from Tier-1/OEM. Contact our sales for more information.